Spray Foam in the Attic

Posted Thu, 10/08/2009 - 08:10 by mattacker

These images are of the insulators spray foaming the attic. They foamed the entire roof truss perimeter, on top of all interior walls, and then gave can lights and other penetrations more insulation and air infiltration protection. This foam insulation is in addition to the loose fill cellulose that gets blown in afterwards.

Drywall hung

Posted Sun, 09/27/2009 - 23:25 by kpbadger

Due to some travel it's been over a week since my prior post, so here is an update on what has been going on at the house.

On Monday (9/21) we met with Laura for the second Energy Star site visit. The second visit is the post-insulation, pre-drywall visit. Because we had opted for the blown-in insulation in the walls and spray foam insulation in selected places, there was not a whole lot to check at this visit.

Throughout the week, the drywall was hung. Here are some pictures taken Wednesday (9/23) in the middle of the project:

The stone on the garage walls and front pillars was also installed, and the fiber cement siding is now completely installed.

By Sunday, the drywall was taped and mudded.

One drywall upgrade that we added was "Quiet Rock" on the wall between the back bedroom and the master bath, and between the office and the adjoining bathroom and laundry room. This product is the same thickness as traditional drywall, but has additional mass to cut down sound transmission. This, along with the insulation in the walls, should make the rooms adjacent to the bathrooms and laundry rooms a bit quieter.

In addition, during the week, some trees between our home and Graber Pond were removed. This is reportedly to improve the habitat for the endangered blanding turtle. A nice side-effect is an improvement of our view of the pond. This picture is taken from the back bedroom window:

Energy Star Site Visit #1 - Report

Posted Sat, 09/19/2009 - 17:31 by kpbadger

I apologize for the delay in posting this - we had our report within a day of the site visit but I wanted to get everybody's permission before just posting it here.

The total report is 7 pages long, consisting of:

- List of requirements for Energy Star certification (with completed items marked)

- List of recommendations based on Laura's observations (many communicated during visit)

- Pictures taken during the visit with comments and further recommendations

Some features of the report that I found particularly interesting included:

- Specific product recommendations (caulk and sealing materials)

- A few pages of the report that were directly addressed to the insulation company

- Various recommendations of things I would never have thought of myself

Here are two sample pages from Laura's report:

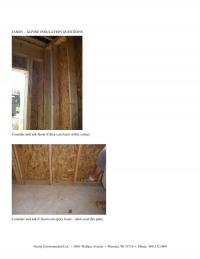

Equally impressive to the turnaround time on the report was the turnaround on the recommendations. The next day, most of the recommendations -- at least those possible without the insulator -- were implemented. The top picture shows a hollow cavity in the corner of the family room with some fiberglass batts shoved in there. The next night, it looked like this, with plenty of room to get blown-in insulation, foam, caulk, etc., in there:

(The fiberglass batt in the above picture was ultimately removed so that blown-in insulation could be installed.)

The next Energy Star appointment is scheduled for Monday, September 21. This second visit occurs after the insulation is done, before the drywall is hung.

Insulation is done!

Posted Fri, 09/18/2009 - 17:35 by mattacker

Today we completed the insulation. This was much more then a standard insulation package. The work was done by Alpine Insulation and included the following:

-BIB (blown in batt) insulation. This is a loose fill insulation that they blow into a netted cavity, and fill it up from bottom to top. It has more R-Value then a standard batt, and has the added benefit of "form fitting" around pipes and wires and such.

-Polyurethane Foam insulation. This is simply the best type of insulation that is readlity available on the residential market. It's R-value and air infiltration specs are very impressive. On Kevin's home, we used this stuff in the most "bang for the buck" areas. Such as a cantalever on the 2nd floor, the floor area that is over the garage, the box sill areas in the basement (since this is an area that naturally draws in air), and area's in the attic will get this as well once the drywall is hung.

-Also caulking of the bottom plates, smart visqueen placement, and other methods were used to make this an extremely air tight house.

Insulation has been inspected and approved, next week: drywall!

Green house from blue to brown

Posted Mon, 09/14/2009 - 23:06 by kpbadger

The official color of our house is Newport Taupe with Brandywine trim and accents.

For the choice of siding material, for us the choice came down to vinyl and fiber cement. The cost to upgrade to fiber cement was over $10,000 (about 150% the cost of vinyl). However, there are both "green" and practical advantages to the fiber cement siding.

http://www.greenhomeguide.com/index.php/knowhow/entry/1304/

http://www.certainteed.com/buildingresponsibly/FiberCementSiding/pdf/CT_FC_GreenTop10_v7.pdf

Our fiber cement is factory-finished and primed on all sides. This means that no painting of the siding is required at the jobsite.

Here are the pictures of the siding installation thus far.